Your Position: Home - Boards - How to produce high-quality building film panels?

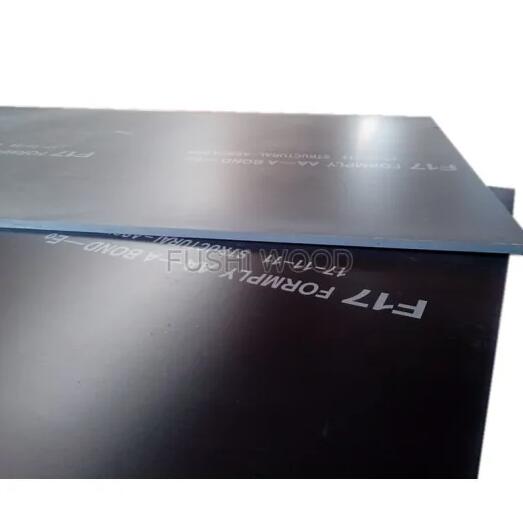

Building film panels are the higher-end building templates currently used in domestic construction. Compared with traditional red templates, the board surface of the template is smoother, more waterproof, and has a higher turnover rate. The price is relatively higher. Good building film panels create good construction projects. How are high-quality building film panels produced?

Raw material cutting

The raw materials of building film panels are obtained by layering and cutting according to logs. The logs are cut and peeled horizontally according to a certain thickness, and cut into wood layers of the same proportion according to the size of the template. The debris on the surface of the wood layer is removed to ensure the cleanliness of the wood layer, which plays an important role in the bonding strength of the later glue.

Drying and drying treatment

The wood layer after cutting and peeling contains a relatively large amount of moisture. Therefore, large-scale production must be dried by a wood dryer. The dried wood layer is relatively brittle. Therefore, it must be left naturally for 2-3 days to ensure the toughness of the wood layer. In small quantities, it can also be dried in the sun.

Gluing and layering

A formed building formwork is glued together by gluing multiple layers of wood boards. A special glue roller is set up. The wood board is passed through the glue roller, and the front and back of the board will be evenly coated with glue. The glue used is generally triamine glue or phenolic glue. The wood board coated with glue is placed flat on the surface of the formwork and evenly laid with 9-10 layers. First cold press, and then apply black film (impregnated paper film).

Hot press molding

The template layer laid after glue coating is flattened by hot pressing. Modern equipment uses electric heating. After flattening, it can increase the density of the building formwork, the molding is more regular, and the quality of the formwork is improved. The process of pre-pressing and then hot pressing is adopted to reduce the probability of dislocation of the blank to the greatest extent, and then reasonable pressure and temperature hot pressing are applied to ensure that each film-coated building formwork has excellent bonding strength and hardness.

Painting, trimming and packaging

After the heat-pressed building template, there will be a small amount of misalignment and irregular corners on the inner wood board. The excess board is cut with a carving knife and sprayed with waterproof paint. Waterproof paint is an important factor in ensuring the service life of the building template and saving time.

127

0

0

Comments

All Comments (0)